TM 3-4240-241-12

e. After the shelter and the filter unit have been

inspected, report the deficiencies to direct support

70. Inlet Damper Adjustment

maintenance personnel.

Adjust the inlet damper when there is a need to

f. To test the canister, start the filter unit motor or

increase or decrease the airflow in the improvised CBR

engine and after a warmup period, check the air

protective shelter (TM 3-350). To increase the airflow,

pressure in the shelter (TM 3-350).

open the inlet damper (1, fig. 13) by moving the damper

g. Adjust the speed of the gasoline engine as

control handle (2) counterclockwise. To decrease the

necessary (TM 5-2805-206-14) to maintain the positive

airflow, close the inlet damper by moving the damper

pressure of filtered air within the shelter.

control handle clockwise.

h. Adjust the inlet damper as necessary.

Section VII. BLOWER GASKET

adhesive.

71. Description and Function

(2) Connect the elbow connector assembly or

The blower gasket is cemented in the recess of the

the air inlet hose assembly and check for

locking coupling adapter. It provides the necessary seal

proper fit and installation of the gasket.

against air leaks when the locking coupling adapter is

connected to either the elbow connector assembly or the

air inlet hose assembly.

72. Maintenance

Organizational

maintenance

personnel

are

authorized to replace the blower gasket.

a. Removal. (Fig. 21)

(1) Disconnect the locking coupling (4) from

the locking coupling adapter (2).

(2) Pry the gasket (3) out of the recess of the

adapter.

b. Inspection and Maintenance.

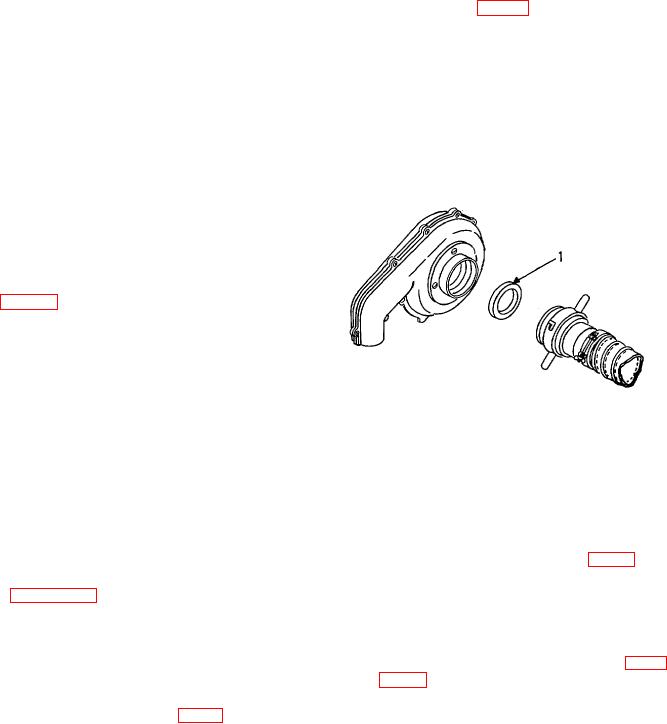

1

Blower

3 Blower gasker

(1) Clean the surfaces of the adapter and

2

Locking coupling

4 Locking coupling

remove all particles of remaining cement.

adapter

5 Locking coupling tube

(2) Wipe the inner ring with drycleaning

solvent. Inspect inner surface for damage.

Figure 21. Blower inlet and blower gasket.

c. Installation.

(1) Cement (MIL-A-3562) the gasket (3) in the

recess of the adapter with liquid rubber

Section VIII. CANISTER ASSEMBLY

b. Remove eight turnbuckles (10, fig. 4), which

73. Description and Function

fasten manifolds and filters together, by loosening

The description and function of the canister

turnbuckle screws.

assembly is given in paragraph 5.

c. Loosen four hose clamps (5, 7, 13 and 16) which

74. Maintenance

fasten two air duct hose (6 and 15).

Organizational

maintenance

personnel

are

d. Extend the four retractable carrying handles (14)

authorized to replace the gas filter, particulate filters,

and carefully lift top manifold (4) with engine (2, fig. 1) or

hose assemblies, and the associated hardware.

motor (2, fig. 2) and blower (3) attached. Place on

75. Disassembly

wooden blocks, being careful not to dent or scratch

Stop engine or motor and perform the following steps:

manifold surfaces.

a. Remove air inlet hose assembly (1, fig. 1) and

air outlet hose assembly (4).

33