d. Idle Adjustment Needle.

let and is controlled by the damper

control handle (2).

Purpose. The canister inlet damper

(1) Location. The idle adjustment needle (1, fig. 12)

(2)

regulates the flow of air into the

is located on the upper carburetor body.

canister. It is set at the factory to

deliver 800 cubic feet of air per

(2) Purpose. The idle adjustment needle is used to

minute.

adjust the fuel-air mixture at idling speed.

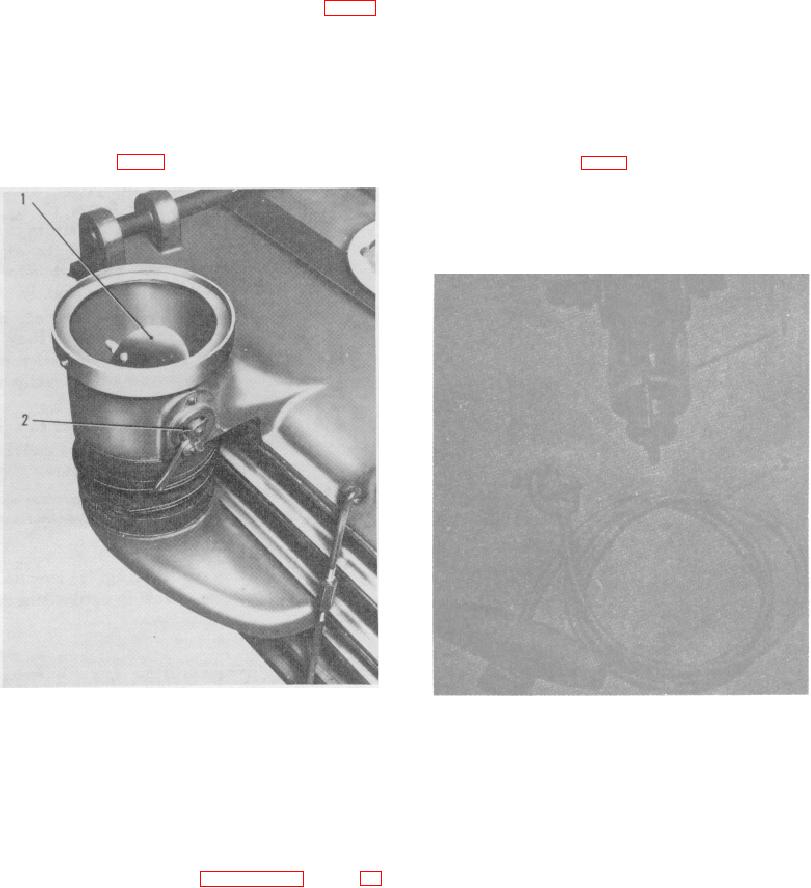

e. Canister Inlet Damper.

11.

Engine Ancillary Assemblies

a. Starting Rope Assembly.

Location The canister inlet damper (1,

(1)

(1) Location. The starting rope assembly

fig. 13) is located in the canister air in-

(2, fig. 14) is packed separately and

crated with the filter unit.

(2) Purpose. The starting rope assembly

is furnished for manually cranking the

engine and must be kept with the

engine at all times.

1

Inlet damper

2

Damper control handle

1. Fuel filter

2

Starting rope

Figure 13. Canister inlet damper.

Figure 14. Gasoline engine ancillary assemblies

Section II. OPERATION UNDER USUAL CONDITIONS

for additional instructions covering operation of the

12.

General

apparatus in extremes of climate and adverse

This section contains instructions for operating the

environmental conditions.

ABC-MI6A1 filter unit under normal conditions of climate

(50F. and above). Refer to paragraphs 17 through 21

13