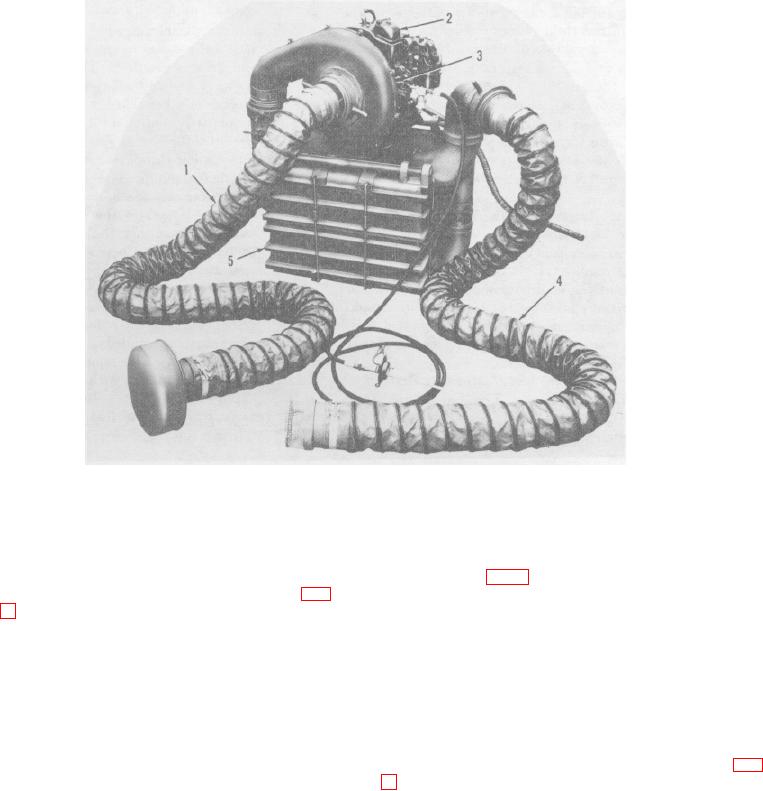

1

Air inlet hose assembly

4

Air outlet hose assembly

2

Engine and accessories

5

Canister assembly

3

Blower assembly

Figure 1. Filter unit, gas-particulate, GED, 300 CFM, ABC-M6A1.

Inside operation. When the ABC-M6A1 filter unit

(1)

shelter (fig. 3), the blower is repositioned and the

blower air outlet is connected directly to the

is operated inside a CBR protective shelter (fig.

canister air inlet. Contaminated air passes

3) the blower air inlet is connected to the canister

directly from the air inlet into the blower air inlet.

air outlet by the elbow coupling. Contaminated

The blower forces the contaminated air through

air passes directly from the air inlet through the

the blower air outlet and the canister air inlet into

canister air inlet into the canister assembly.

the canister group. Purified air leaving the

Purified air leaving the canister assembly passes

canister group passes through the canister air

through the canister air outlet into the blower air

outlet and air outlet hose assembly into the CBR

inlet. The blower forces purified air through the

protective shelter.

blower air outlet directly or through the air outlet

hose assembly into the CBR protective shelter.

b. Canister Assembly. The canister assembly (fig.

4) consists of a canister containing a top manifold (4),

Warning. Do not use the ABC-M6A1 filter

bottom manifold (9), intake manifold (19), two 150 CFM,

unit as a ventilating system. The ABC-M6A1

M9A1 particulate filter (8), and two 150 CFM, M10 gas

filter unit is not equipped with a bypass

filters (11). The components of the canister are fastened

mechanism. Such operation will shorten the

together by eight turnbuckles (10). The canister is car-

life of the filters and subsequently en-

dangered human life.

Outside operation. When the ABCM6A1 filter

(2)

unit is operated outside the CBR protective

3