TM 5-4330-263-13&P

OPERATOR AND FIELD MAINTENANCE

FILTER/SEPARATOR, LIQUID FUEL, 50-, 100-, AND 350-GPM

TROUBLESHOOTING

INTRODUCTION

Table 1 lists common malfunctions that you may find with your equipment. Perform the tests, inspections, and corrective

actions in the order they appear in the table. This table cannot list all the malfunctions that can occur, all tests and inspec-

tions needed to find the fault, or all the corrective actions needed to correct the fault. If the equipment malfunction is not

listed or actions listed do not correct the fault, notify your supervisor.

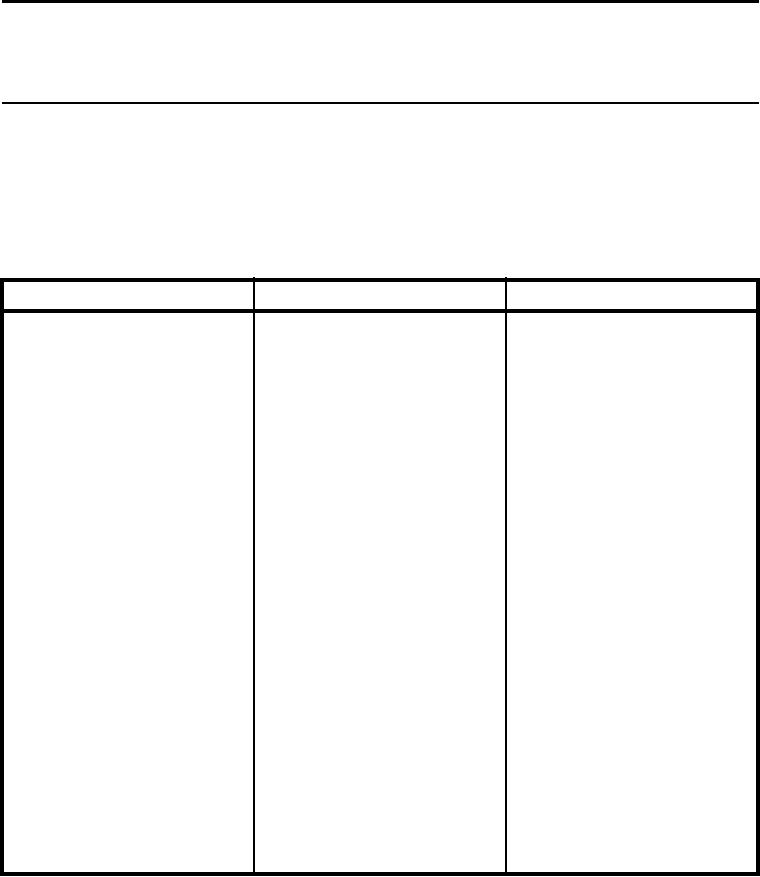

Table 1. Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Differential pressure gauge indication is 1.

Check pump operating speed and

1.

Adjust pump speed as necessary

in the RED area of the gauge.

verify that it is within specified

limits

2.

Coalescer element contaminated

2.

Immediately cease operation and

replace all canisters and coalescer

elements

1.

Verify that camlocks are securely

1.

Secure camlocks properly

Fuel leaking from input or output

coupling

fastened

2.

Stop operation and inspect

2.

Properly seat gaskets or replace

couplings to verify that gaskets are

defective gaskets

in place, properly seated, and free

from damage

Fuel leaking from vessel cover

1.

Check retaining band (50- and 100- 1.

Ensure retaining band locks

GPM) nuts for proper tightness.

properly, with nut torqued to 14 ft-

lbs. (50- and 100-GPM).

2.

Check lid nuts (350-GPM) for

2.

Ensure lid bolts are torqued to 150

proper tightness

ft-lbs. (350-GPM).

3.

Inspect head assembly o-ring for

3.

Remove head assembly and replace

wear or damage

o-ring

1.

Check for ruptured coalescer

1.

Replace all coalescer elements

Sudden drop in differential pressure

gauge indication

elements

1.

Check pump flow rate and

1.

Perform maintenance on pump

Filter/Separator output flow is

inadequate

performance

2.

Inspect discharge line for kinks or

2.

Remove obstructions and

obstructions

straighten line as necessary

3.

Check differential pressure gauge

3.

If reading is above limit, cease

and verify that reading is within

operations and replace all coalescer

limits (below red/15)

elements.

END OF WORK PACKAGE

0008 00-1/(0008 00-2 blank)