TM 5-4330-263-13&P

0006 00

OPERATION UNDER USUAL CONDITIONS

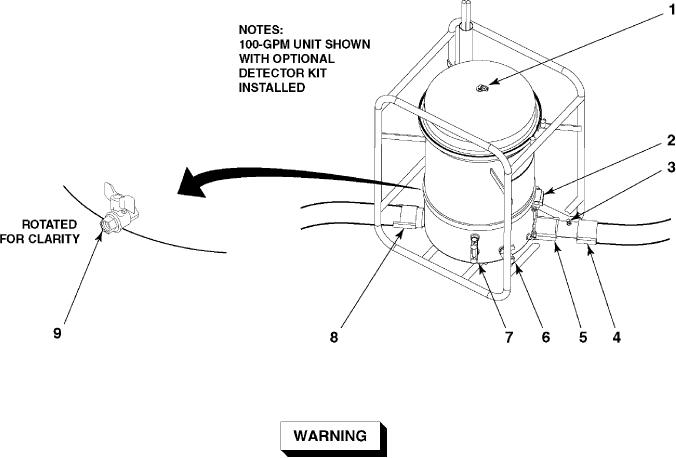

Figure 1. Filter/Separator Unit Operation

In normal operation, the filter/separator is filled with diesel/jet fuel. Diesel/jet fuel may explode if

subjected to high temperatures, sources of ignition or high pressure. Keep all open flames, cigarettes,

and any other sources of fire/flame or ignition a minimum of 50 yards from any fuel servicing

operations. Failure to follow this warning may result in injury or death to personnel.

Diesel/jet fuel fumes are toxic in high concentrations. Avoid prolonged breathing of vapors. Operation

and maintenance of the filter/separator should be performed only in a well-ventilated environment.

Failure to follow this warning may result in injury or death to personnel.

Diesel/jet fuel is toxic and can severely affect skin, eyes and the respiratory tract. Personnel must wear

appropriate hand and eye protection (nitrile gloves and goggles). Wash skin thoroughly with soap and

water if exposed. In case of contact with diesel/jet fuel, flush eyes with clear water for at lest 15

minutes . Failure to follow this warning may result in injury or death to personnel.

NOTE

The detector kit can be placed in inlet or outlet side of vessel.

1.

If fuel sampling will be conducted, install detector kit (figure 1, 3) on filter/separator inlet or outlet connection (5 or

8) and close camlocks completely.

2.

With the pump turned off and no fuel flowing, attach supply hose to inlet connection (5) and close camlocks com-

pletely.

3.

Attach fueling hose to outlet connection (8) and close camlocks completely.