Check tapped holes for stripping or cross-

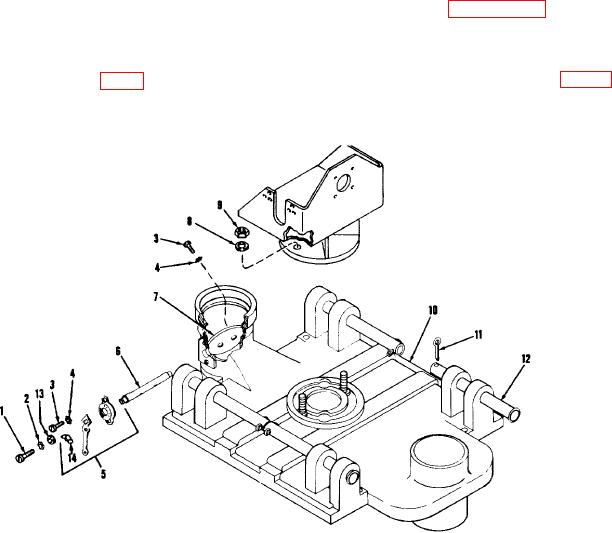

(2) Position two spacer blocks (2) between

threading.

gasoline engine and engine stand

assembly with chamfered edges toward

engine.

c. Repair.

(3) Install six 1 3/8-inch long capscrews (5)

and lockwashers (4) through engine stand

(1) Repair cracks in engine stand assembly

assembly and spacer blocks and screw

by inert gas welding. Dress all welds if

into engine.

required to prevent interference. Chase

(4) Install six 3/4-inch long capscrews (6) and

cross-threaded holes with a 3/8-16 UNC-

lockwashers (4) in opposite side.

2B tap.

Assemble and install blower assembly as

(2) Repair for the gasoline engine is

described in paragraph 14d.

contained in TM 5-2805-206-14.

(5) Place engine, stand assembly, and blower

d. Assembly and Installation.

assembly as one unit on swivel base of

top manifold assembly and secure with

two self-locking nuts (9, fig. 4) and

(1) Place gasoline engine (1, fig. 3) on engine

washers (8).

stand assembly.

8. Washer

1.

Machine screw

9. Self-locking

2.

Lockwasher

10. Top manifold

3.

Machine screw

11. Cotter pin

4.

Lockwasher

12. Carrying handle

5.

Dial regulator assembly

13. Washer

6.

Shaft

14. Wingnut

7.

Damper

Figure 4. Top manifold assembly.

AGO 8757A

8