with hose clamps (5, 7, 18 and 16). Inspect hose for

41. Function

damage, tears, or punctures.

The canister removes toxic gases, dust, and

b. Turnbuckle. Check turnbuckle (10) on all four

aerosols (solid and liquid particles) from the atmosphere

sides of canister assembly. See that turn- buckles are in

and delivers 300 cubic feet of purified air per minute.

place and tighten if necessary.

The airflow of contaminated air is given in paragraph 5.

c. Elbow Connector Assembly and Slide Bolt.

Check the elbow connector assembly (6, fig. 8) to see

42. Maintenance

that it is in working order. Rotate the elbow connector

The operator is authorized to inspect, service, and

assembly to different locations and check for full and

adjust the following component parts of the canister

easy movement. Check the slide bolts (10, fig. 16),

assembly.

Any defect should be reported to

washers (8) and self- locking nut (9) for wear, and

organizational maintenance personnel.

damaged threads.

d. Dial Regulator Assembly. Check the dial

a.

Hose Assemblies.

Check the air hose

regulator (7, fig. 16) to see it operates properly and is in

assembly (6, fig. 4) and air hose assembly (15) to see

working order. Check for wear, damage, and missing

they are connected properly and fastened securely

parts.

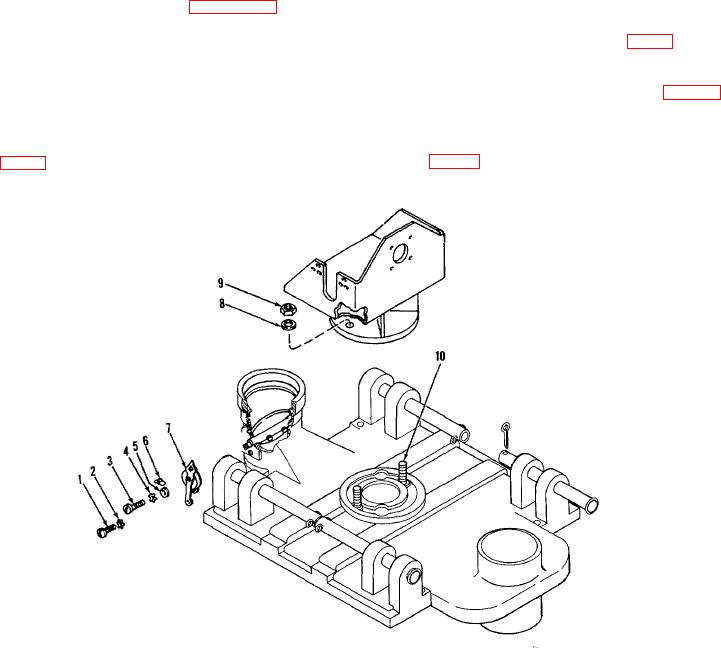

1

Machine screw

6

Wing nut

2

Lock washer

7

Dial regulator assembly

3

Machine screw

8

Washer

4

Lock washer

9

Self-locking nut

5

Washer

10

Slide bolt

Figure 16. Top manifold assembly

21