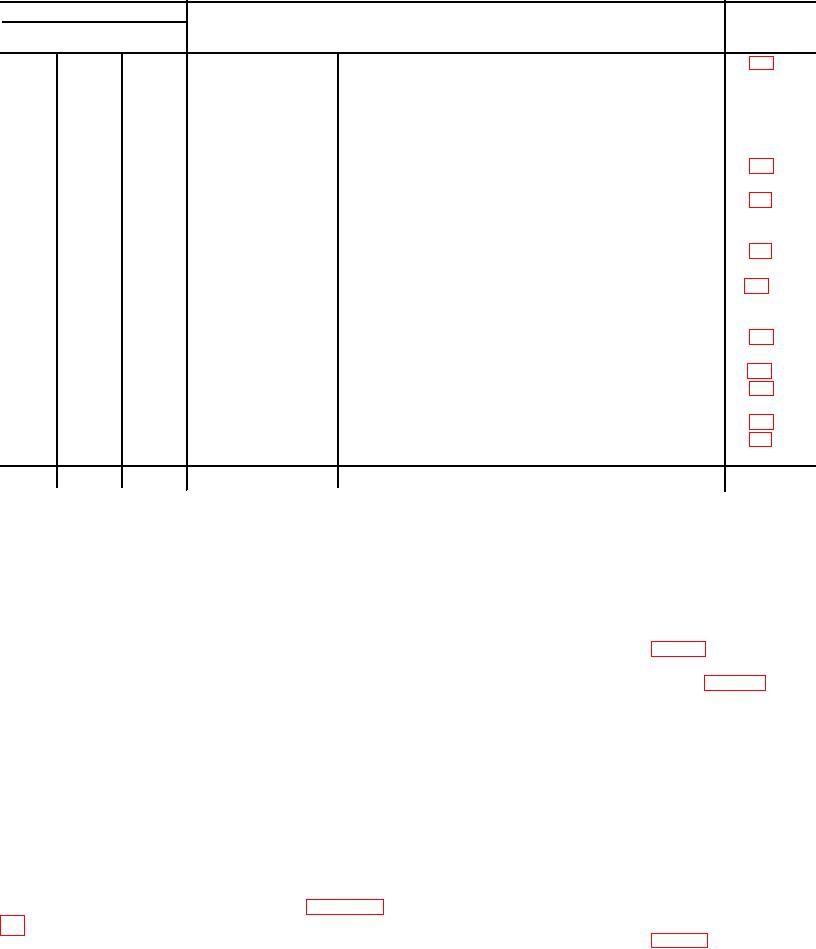

Preventive Maintenance Checks and Services

Operator Daily Schedule

Interval and sequence no.

Before During

After

Item to be inspected

Procedure

Paragraph

operation operation operation

reference

1

13

Publications ............

See that copies of

TM3-4240-241-12

TM 3-4240-241-20P

TM 5-2805-206-14,

TM 5-2805-206-24P, and

LO 5-2805-206-14 are packed with the equipment.

2

Filter unit ................

Make certain that the ABC-M6A1 filter unit is on

27a(2)

firm, foundation.

3

9

14

Canister assembly..

Inspect all edges for tight closure. Check for holes,

27a(5)

evidence of moisture, leakage, and for chafing or

obstructions in air inlet and outlet

4

15

Blower assembly ....

Check blower inlet and outlet for obstructions, dents,

27a(5)

or sign of damage

5

10

16

Air inlet and outlet...

Be sure air inlet and air outlet hose assemblies are prop-

27a(4)

hose assemblies.

erly connected for inside or outside operation as re-

quired. Check for loose connections and leaks.

6

17

Fuel ........................

Fill fuel gasoline can. Be sure reserve fuel supply is

adequate.

7

11

18

Engine ....................

Perform all Operator's daily services...............................

8

19

Lubrication..............

Check all oil levels in accordance with LO 5-2805-206-

...............................

14. Inspect air cleaner and fuel filter as required.

12

Unusual operation ..

Listen for rattles, hums or knocks ...................................

28c, d

20

Protection ...............

Inspect, clean and cover unit and store reserve fuel

supply in safe area

Section IV. TROUBLESHOOTING

31.

General

33.

Excessive Airflow

This section contains information useful for locating

Probable cause

Possible remedy

and correcting malfunctions which may develop in the

ABC-M6A1 filter unit. Each malfunction is followed by a

Filter loose or damaged ---------- Report to organizational

description of probable causes and possible remedies.

maintenance personnel.

Remedies which must be applied by higher categories of

Gasoline engine running at ........ Adjust engine speed

maintenance personnel include a note to this effect. See

excessive speed

(para. 8b)

TM 5-2805-206-14 for detailed engine troubleshooting.

Canister inlet damper not -------- Adjust canister Inlet

correctly adjusted. ----------------- damper(para. 27a(5)).

32.

Gasoline Engine Fails to Start

34.

Insufficient Airflow

Probable cause

Possible remedy

Probable cause

Possible remedy

lack of fuel ---------------Fill five gallon engine supply can

with fuel.

Particulate filter clogged ---------- Report to organizational

Carburetor flooded -----Adjust choke and crank engine.

maintenance personnel.

Water or dirt In fuel -----Drain fuel from gasoline can,

Obstruction in air inlet ------------- Remove obstruction.

adapter, and hose assembly.

hose, canister air Inlet,

Drain fuel from supply can and

or blower air inlet

refill.

Obstruction in air outlet ----------- Remove obstruction

hose, canister air outlet,

or blower air outlet

Note. For engine troubleshooting beyond this

Canister inlet damper not

Adjust canister inlet

point refer to manual TM 5-2805-206-14, paragraph

correctly adjusted

damper or engine speed

22. This manual is part of the ABC-M6A1 filter unit

(para 37c (5) or 8).

and is with the engine.

19