Section V. MAINTENANCE PROCEDURES

2-9. PERSONNEL SHOWER ASSEMBLY.

This task covers:

c. Repair

a. Disassembly

d. Reassembly

b. Cleaning

INITIAL SETUP

Polyurethane coating (item 28, app D)

Tools and Special Tools

Sealing compound (item 31, app D)

Automotive Maintenance and Repair Shop Equipment, Less Power

(SC 4910-95-CL-A72 and SC 4910-95-CL-A74)

References

Materials/Parts

Antisiezing tape (item 35, app D)

Equipment Condition

General purpose detergent (item 12, app D)

Personnel shower assembly is removed from tank unit. See

Metallic pipe (fig E-4)

REMARKS

ACTION

LOCATION/lTEM

For cleaning and repair of sediment strainer (3), see

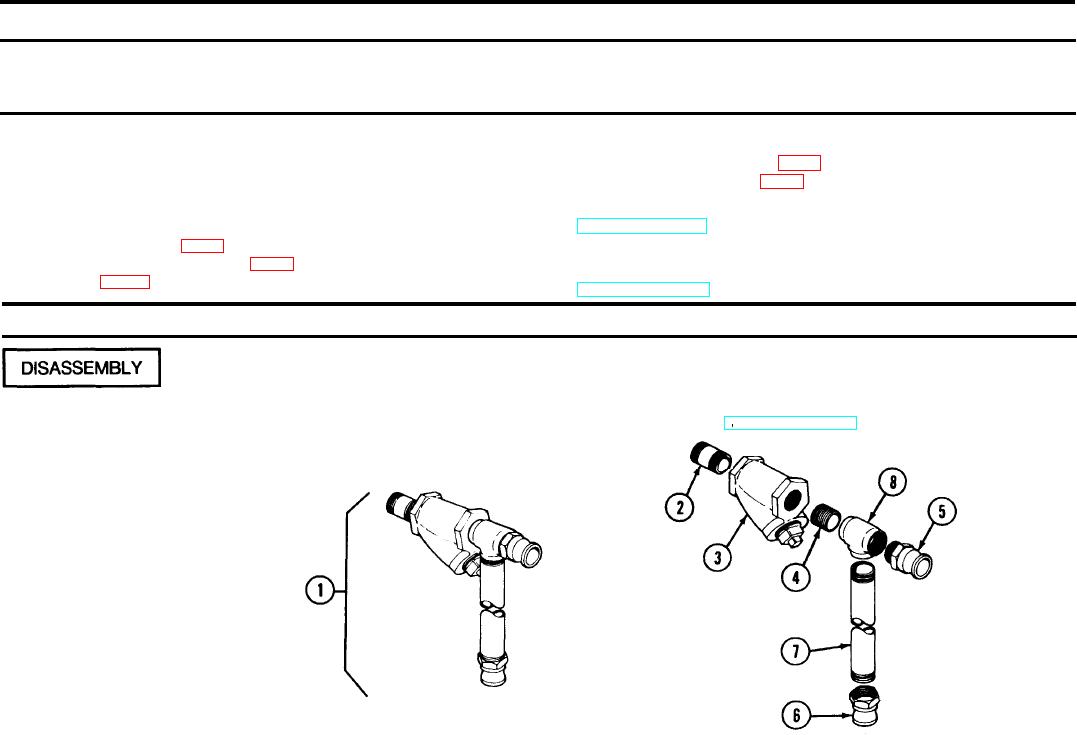

Disassemble upper front support (1) by unscrewing pipe nipple (2), sedi-

Personnel Shower Assembly/

ment strainer (3), pipe nipple (4), coupling half with male threads (5),

Upper Front Support

couplinhg half with female threads (6), and pipe (7) from pipe tee (8).

TM 3-4230-209-20&P

2-31