(3) When the water hose is connected to the agitation quick discon-

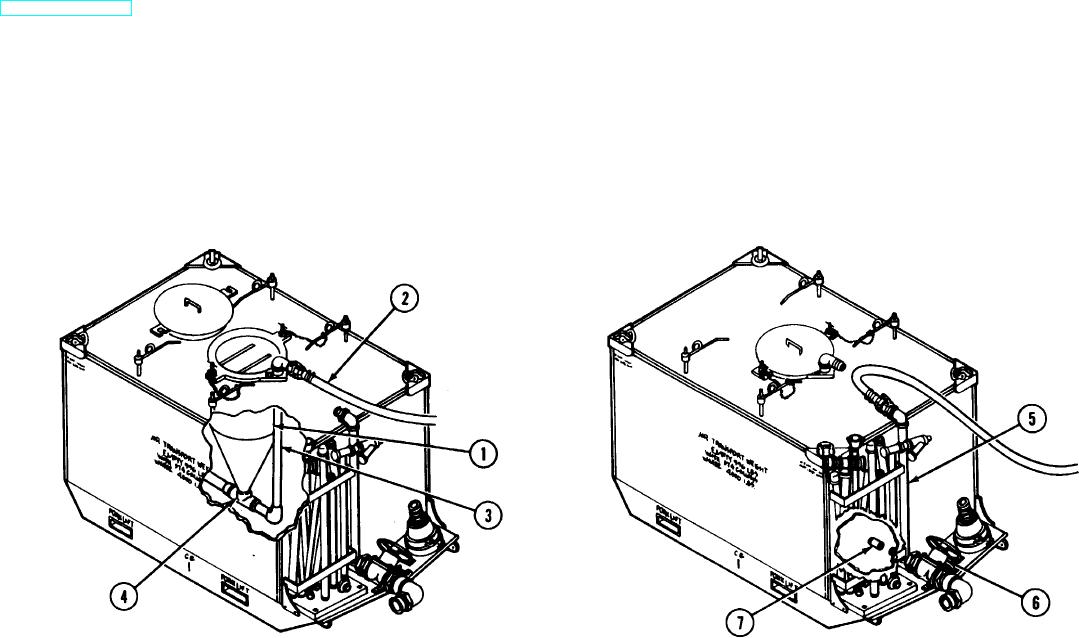

c. Tank Unit.

nect on the end of the tank unit, water flows as follows:

(1) The tank unit hopper tank (1) passes bulk powder or chemicals into

(a) VALVE NO. 1 MANIFOLD controls the flow of water from the

the tank unit for mixing.

(upper) DISCHARGE quick disconnect. The lower DISCHARGE quick discon-

(2) When the tank unit is connected to the pump unit according to

nect is controlled only when capped. When uncapped, it can be connected

TM 3-4230-209-10, water flows through various routes depending on the

through a water hose to the agitation quick disconnect.

mode of operation required. When the blender hose is connected to the quick

(b) The flow of water is routed down through the pipe (5) mounted

disconnect on the hopper and to the upper DISCHARGE port on the pump,

to the outside of the tank. The pipe is elbowed into the tank unit very near the

water flows as follows:

bottom of the tank and near the tank drain valve (6). On the end of a small

(a) VALVE NO. 1 MANIFOLD controls water flow out the upper

length of pipe just inside the tank is an agitation nozzle (7). Water passing

DISCHARGE port through the blender hose (2) and into the hopper assembly

through this agitation nozzle is changed from a direct flow to an aeration type

quick disconnect.

flow. This aerated water is discharged into the water and aerates the slurry

(b) Water is forced down the pipe (3), past a small opening (4) in

mixture. The aerated slurry mixture is agitated and cannot fall to the bottom of

the bottom of the hopper tank (1), and discharged into the water inside the tank

the tank and become useless. It is forced to rise in the water because of the

unit. Water, passing through the small opening (4), causes a vortex (small tur-

effect of the air bubbles.

bulence) action. This vortex mixes an amount of powders or chemicals in nearly

direct proportion to the water flow. Water mixes the chemicals as long as it

flows through the hopper.

TM 3-4230-209-20&P

1-21