to the fuel pump and ignition drive motor (MOTB2). When the fuel pump and

NOTE

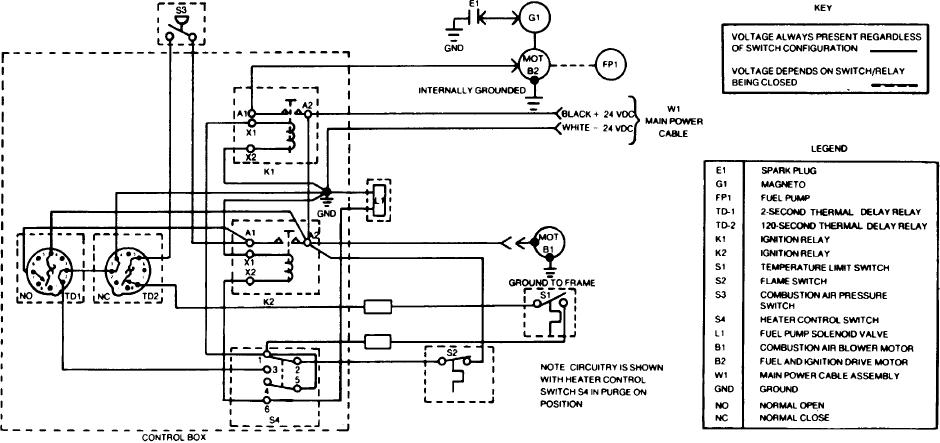

The next few steps are also shown in the schematic form and

ignition drive motor is operating, fuel is pumped from the fuel supply through

the water heater. Since the fuel pump solenoid valve is not powered, all the fuel

these are time cycles.

is returned back to the source. At the same time the magneto is being driven to

produce a very high voltage which is sent to the combustor chamber to the

(6) The main power cable positive (black) wire connects 24 vdc to

igniter (E1) which begins to spark. Any fuel or fuel vapors will be burned off

relays K1-A2, K2-A2, MOT B1 (combustor fan motor) TD1-5, through switch

before additional fuel is supplied. Operate in PURGE ON for at least two

S2 (flame switch) and switch S4-2 (HEATER ON PURGE ON). The power

minutes before moving HEATER ON/PURGE ON SWITCH (S4) to HEATER

should always beat these points regardless of the S4 position. When the

ON. The second branch is a fail-safe circuit. From terminal S4-1 power is

combustor fan (MOT B1) is operating, it will build up a pressure. This pressure

connected through the contacts of S1 (thermostatic switch), located in the top

closes the contacts of S3 (combustion air pressure switch) when pressure is

of the boiler, through pin 7 and 5 of TD-2 (thermal delay-120 seconds), and on

greater than 1 1/4 inches of water (gage).

through S3 which was closed by the air pressure in the terminal combustor

(7) With S4 switch placed to PURGE ON (as shown) the 24 vdc is con-

unit. The voltage leaves S3 and is connected to relay K2 terminal A1 and onto

netted to two branch circuits. The first branch from S4 terminal 1 is connected

pin 7 of TD-1 (thermal delay-2 seconds normally open). This branch is stopped

to relay K1 through X1 and X2 to ground. This closes the contacts to allow the

by the open contacts at both K2-A1 and TD1-7.

24 volts applied to A2 to pass through closed contacts, out terminal A1, and on

1-17

TM 3-4230-209-20&P