TM 11591522613

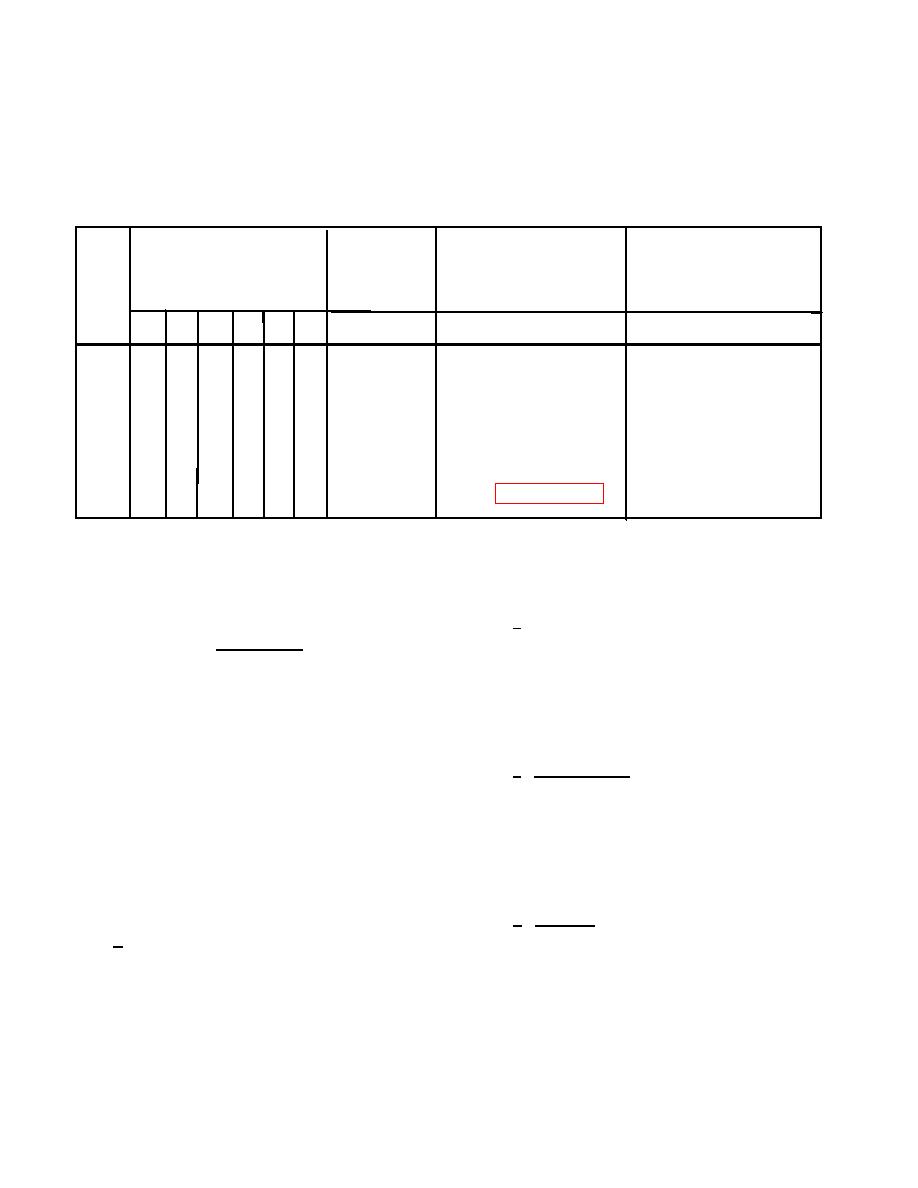

Table 4-1. Organizational Preventive Maintenance Checks and Services

W Weekly

Q Quarterly

A Annually

M Monthly

S Semiannually

B Biannually

For readiness reporting,

Item

Interval

Item to be

Procedures

equipment is not

No.

Inspected

ready/available if:

WMQ

S

A

B

1

X

Installation

Check to see that

Operation is impaired.

equipment is properly

installed.

Give the F-1461/VRC

2

X

Operational

Operation is impaired.

Check

an operation check fol-

lowing paragraph 3-3.

c. Clean cable connectors with trichloro-

__________

trifluoroethane. Male contacts should be wiped

WARNING

with the same solution. Female contacts should

Adequate ventilation should be provided while

be cleaned in the same way, using a soft brush.

using TRICHLOROTRIFLUOROETHANE.

4-6. Rustproofing and Painting

Prolonged breathing of vapor should be

avoided. The solvent should not be used near

a. Rustproofing. When the finish on the

heat or open flame; the products of decomposi-

F-1461/VRC has become badly scarred or dam-

tion are toxic and irritating. Since

aged, rust and corrosion can be prevented by

TRICHLOROTRIFLUOROETHANE dissolves

touching up the bare spots. Use No. 000 sand-

natural oils, prolonged contact with skin must

paper to clean the surface down to bare metal.

be avoided. When necessary, use gloves that

Obtain a bright smooth finish.

the solvent cannot penetrate. If the solvent is

taken internally, consult a physician immedi-

b. Painting. Apply primer; after drying,

ately.

brush two thin coats of paint on the bare metal

b. Remove grease, fungus and ground-in-

dirt from equipment using a cloth dampened

to protect it. Refer to the applicable cleaning

(not wet) with trichlorotrifluoroethane.

and refinishing practices specified in TB 746-10.

42