TM 10-4330-236-13&P

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4-7. GENERAL

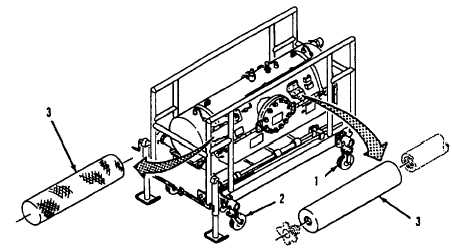

To ensure the 200 GPM filter-separator is ready at all times, it must be inspected systematically so defects are corrected

before serious damage or equipment failure occurs. The necessary Preventive Maintenance Checks and Services

(PMCS) to be performed are listed in Table 4-1. Defects discovered during operation of the unit should be corrected as

soon as possible. All deficiencies and corrective actions will be recorded on DA Form 2404 (Equipment Inspection and

Maintenance Work sheet). Items to be inspected are shown in figure 4-2.

Table 4-1. Unit Preventive Maintenance Checks and Services for 200 GPM Filter-Separator.

Item

Location

Not Fully Mission

No.

Interval

Item to

Check/Service

Procedure

Capable If

1

Monthly

Rigid Wheel

a.

Inspect for bent mounting and

Bent mounting, tire

Assembly

damaged tire. If tire low. inflate to

damaged.

60 psi.

b.

Lubricate rigid wheel assemblies

with GAA, per MIL-- 10924.

2

Monthly

Swivel Wheel

a.

Inspect for bent mounting, stuck

Bent mounting, swivel

Assembly

swivel, and damaged tire. If tire low,

stuck, or tire damaged.

inflate to 60 psig.

b.

Lubricate wheel assembly with GAA,

per MIL-G-10924.

3

Bi-monthly

Filter Elements

Replace first stage and second stage filter

Service overdue.

elements.

Figure 4-2. Unit PMCS Items.

4-5