TM 10-4330-234-13&P

SECTION III. UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

Paragraph

Page

General ...............................................................................................................

PMCS Procedures ...............................................................................................

4-8. General. Unit level maintenance PMCS are done to ensure that the filter/separator is in operating

condition. A comprehensive PMCS program reduces equipment downtime and increases the operational

readiness of the filter/separator.

show the order in which the check or service should be done. These numbers should be used when recording

deficiencies and shortcomings on DA Form 2404. Equipment inspection and Maintenance Worksheet. The in

the interval column indicates when a check or service should be done, as follows:

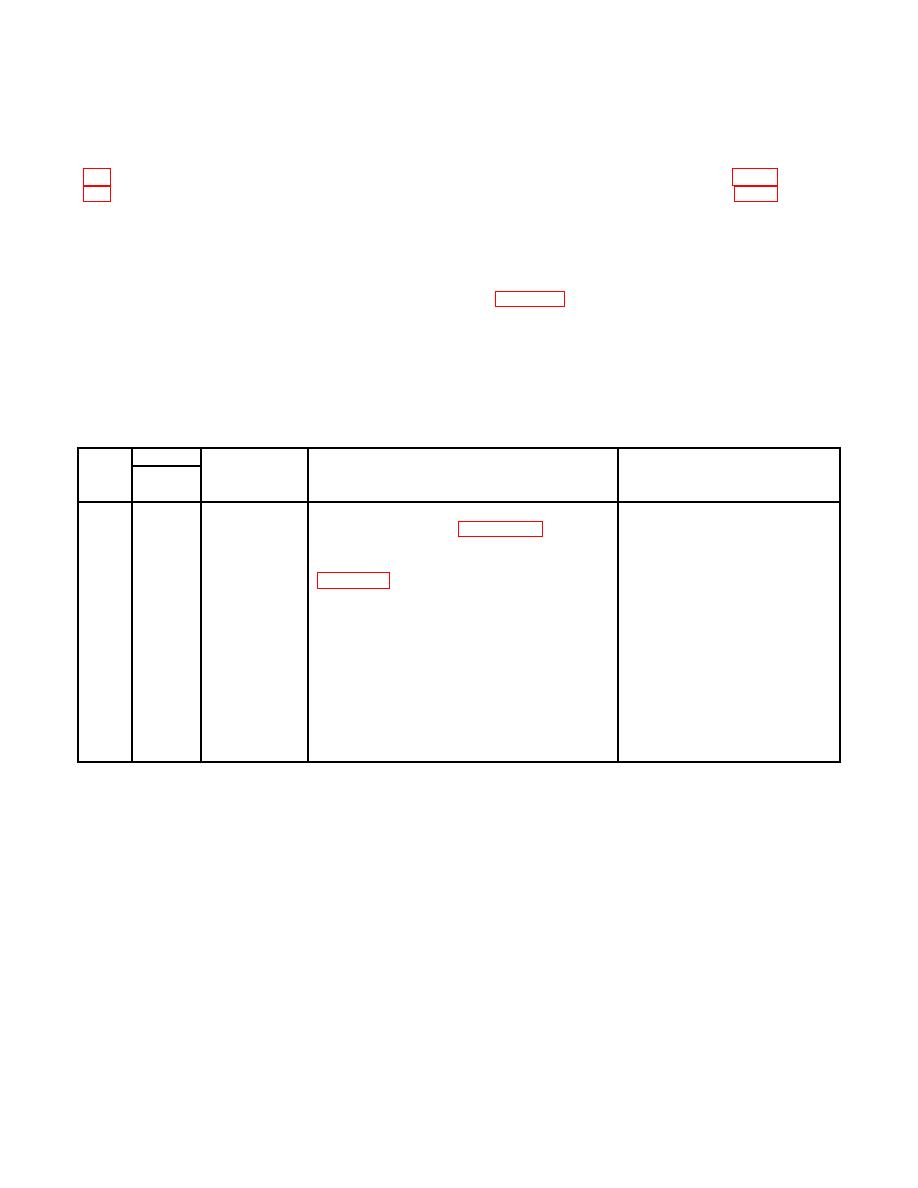

Table 4-1. Unit Preventive Maintenance Checks and Services (PMCS).

M - Monthly

Interval

Item

Item to be

Procedures

Equipment is not

No.

M

Inspected

Ready/Available If:

Clamp band is damaged.

1

Clamp Band

Remove tank cover (para. 4-12). Inspect

for cracks, breaks and other damage. If

any damage exists replace clamp band

2

Pressure

Inspect for cracks, breaks and any other

Pressure relief

valve

is

Relief Valve

damage.

damaged.

3

Manual Drain

Inspect for cracks, breaks or other damage

Manual

drain

valve

is

Valve

damaged.

4

Automatic

Inspect for cracks, breaks or other damage

Automatic drain

valve

is

Drain Valve

inoperable.

4-4