TM 10-4330-234-13&P

CAUTION

Equipment operation is allowable with minor leakage (Class I or II) of any fluid

except fuel. Of course, consideration must be given to the fluid capacity in the

item being checked/inspected. When in doubt, notify your supervisor.

When operating with Class I or Il leaks, continue to check fluid level more often

than required in the PMCS.

Class III leaks should be reported to your supervisor or unit maintenance.

e. Painting. Touch-up filter/separator as needed. Refer to TM 43-0139 for specific painting procedures.

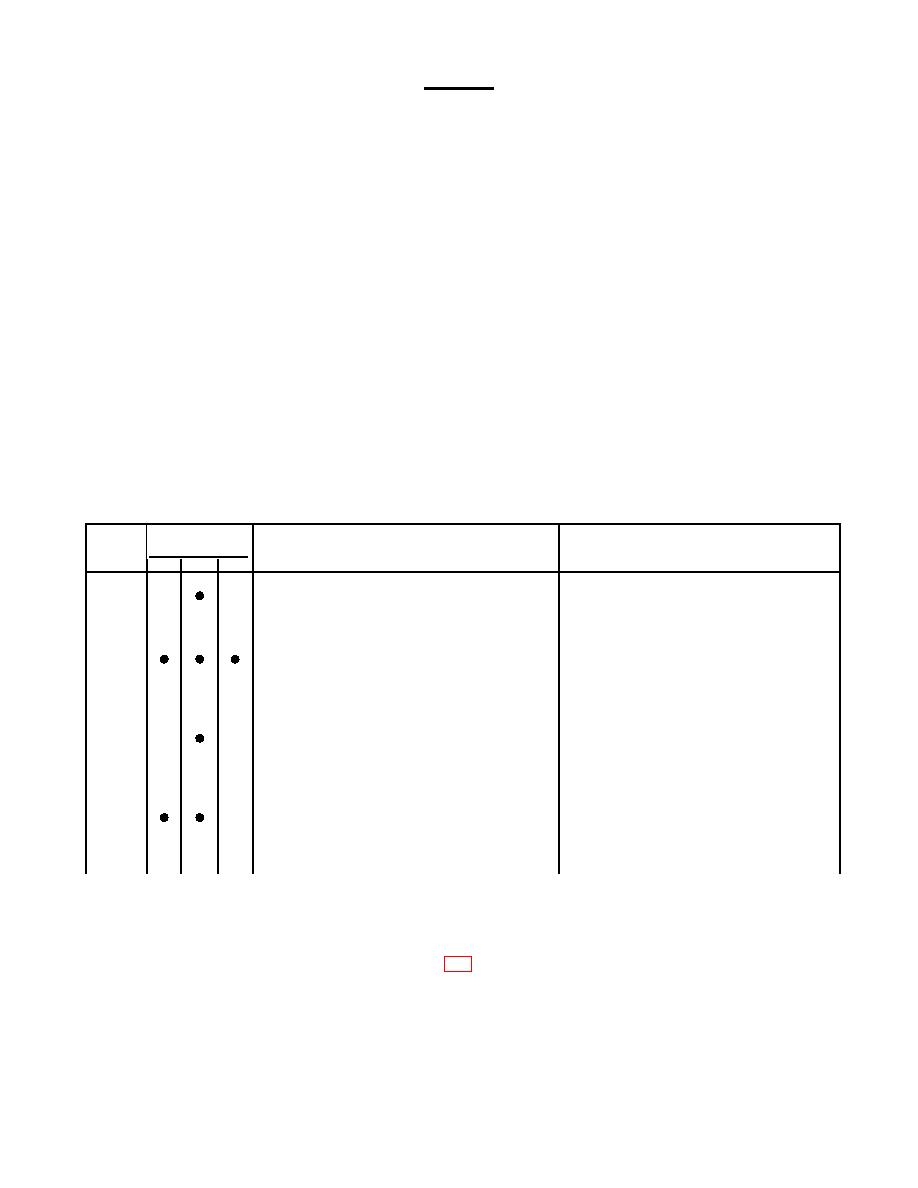

Table 2- 1. Operator Preventive Maintenance Checks and Services (PMCS).

NOTE

Within designated intervals, these checks are to be performed in the order listed.

If the equipment must be kept in continuous operation, check and service only

those items that can be checked and serviced without disturbing the operation.

Make the complete checks and services when the equipment can be shut down.

B - Before

D - During

A - After

Interval

Item

Item to be Inspected

Equipment is Not

No.

B

D

A

Procedure

Ready/Available If

1

SAFETY RELIEF VALVE

Safety relief valve inoperative.

Check Safety relief valve operation for clogs.

2

TANK COVER

Check tank cover for missing bolts, washers,

Cover is cracked or packing is leaking

nuts, dents, cracks or leaking packing.

fuel. Bolts, washers or nuts are

missing.

3

DIFFERENTIAL PRESSURE GAGE

Check differential pressure gage for safe

Pressure differential gage is damaged,

reading (35 PSI). Check for broken glass.

or reads over 35 PSI.

4

SIGHT GAGE

Check sight gage for broken glass or leaks

Sight gage is broken or leaking