TM 5-4330-263-13&P

0002 00

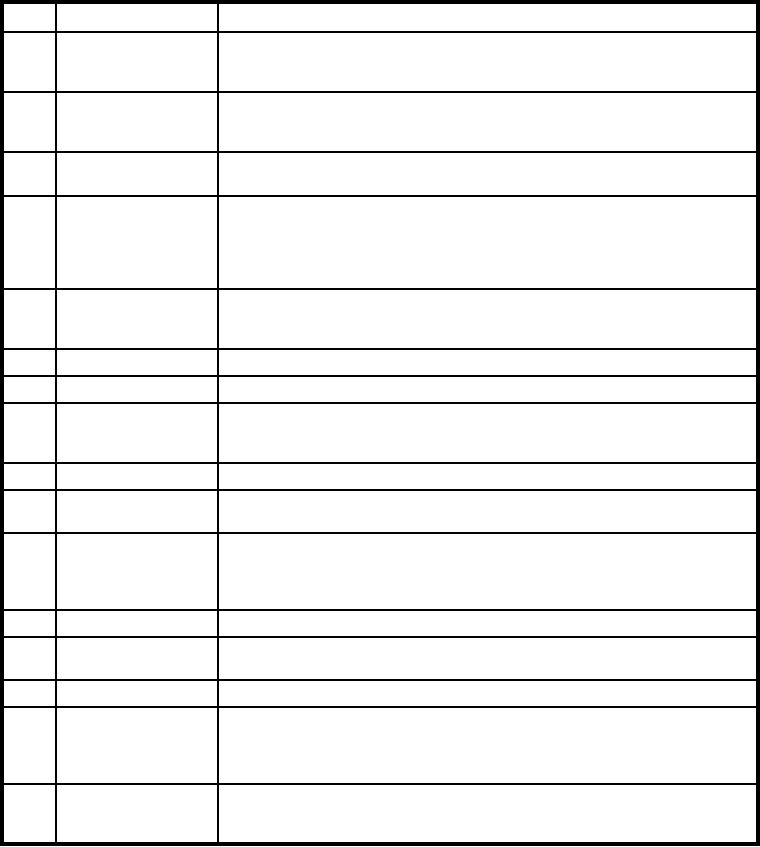

Table 2. 100-GPM Filter/Separator Major Components

No.

Item

Description

1

Ground Rod

The grounding rod is driven into the ground and connected to the frame using a cop-

per cable. The grounding rod allows for the dissipation of static electricity that

would otherwise build up in the unit as fuel flows through the vessel.

2

Head Assembly

The head assembly is a removable cover secured to the top of the vessel by a stain-

less steel retaining band. The head assembly is removed to allow access to the coa-

lescer elements inside the vessel.

3

Retaining Band

The retaining band is a stainless steel belt that is used to secure the head assembly to

the top of the vessel A bolt mechanism is used to tighten the retaining band in place.

4

Differential Pressure

The differential pressure gauge displays the pressure difference across the filter/sep-

Gauge

arator elements. When filter elements become contaminated, the flow through the

elements is impeded, causing an increase in pressure. The Operator monitors the dif-

ferential pressure gauge and changes the elements when the pressure difference

exceeds a threshold value.

5

Inlet Coupling

Fuel to be filtered enters the vessel through the inlet coupling located at the bottom

of the vessel. The inlet coupling is a standard camlock-type connection for fuel

hoses.

6

Water Drain Valve

A lever-operated ball valve used by the Operator to evacuate water from the sump.

7

Canister

The canister separates the coalesced water from the fuel.

8

Coalescer

The coalescer is the primary filtering component of the filter separator. The coa-

lescer coalesces suspended water and removes particulate matter from the fuel

before it exits the Filter/Separator through the outlet.

9

O-ring

The o-ring provides a seal between the head assembly and the vessel.

10

Bayonet Mount

The bayonet provides a mounting surface for the canisters containing the coalescer

elements.

11

Detector Kit

The detector kit consists of a short pipe nipple with camlock fittings on either end

that allow it to be installed in the outlet flow of the filter/separator unit. The nipple is

equipped with a probe that allows for sampling of the fuel exiting the filter/separator

for testing purposes.

12

Sight Gauge

The sight gauge indicates to the operator the level of water collected in the sump.

13

Outlet Coupling

Filtered fuel exits the vessel through the outlet coupling at the bottom of the vessel.

The outlet coupling is a standard camlock-type connection for fuel hoses.

14

Fuel Drain Valve

A lever-operated ball valve used by the Operator to evacuate fuel from the vessel.

15

Frame and Vessel

The vessel and frame are a single, welded assembly. The vessel contains the coa-

lescer elements of the filter/separator assembly. The frame protects the vessel and

attached components from damage and provides a stable, level mounting platform

for the vessel.

16

Purge Valve

The purge valve is located on top of the vessel's cover assembly. The Operator acti-

vates the purge valve to allow air trapped inside the vessel to escape with minimal

fuel loss.

0002 00-5